REINVENTING THE AUTOMOBILE

The story of how we transformed the automotive industry

THE REINVENTION OF THE AUTOMOBILE PROGRAM

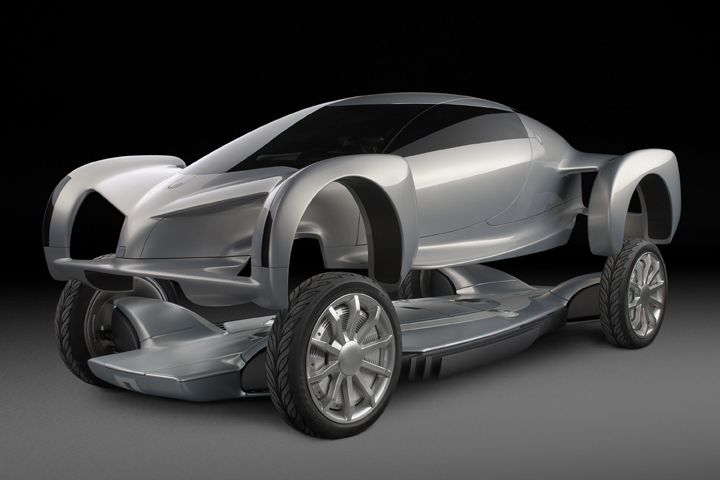

It all began with the GM Autonomy, a vehicle claimed by David Cole from the Center of Automotive Research as “the biggest thing to happen in the last 50 years of transportation”. Over the course of the 5 year invention, creation, development and delivery of several game-changing concept vehicles it has evolved into a multitude of concept and production vehicles including Telsa Motors, the Chevy Volt and the VW MEB Platform.

What we did was to answer how to reinvent the automobile—and the end results—far exceeded expectations. Innovations and developments achieved as a result of this far-reaching initiative yielded a series of design and technology vehicles that have since been showcased and driven all over the world. Nearly 50 awarded patents have come out of this program, and the world now holds the keys to a revolutionary electrified vehicle skateboard platform. The advanced technologies that the GM AUTOnomy and its successors brought to the table not only changed the perception of the automobile, they broke the automotive mold by loosening the constraints and freeing up transportation with improved customer experiences and autonomous capabilities.

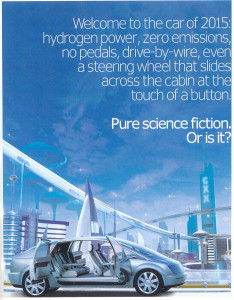

To help you understand how we created and believed in this future vision of transportation, we must walk you through its inception. This will be helpful in understanding the genesis and the delivery of a game-changing Moon Shot. To get there, we must pursue each evolution backwards in order to bring our vision closer to becoming a reality. The Chevy Volt—the first plug-in hybrid vehicle and the first one of its kind to be mass-produced for the public—has paved the way for us to reach this ultimate future, a future that includes many innovative elements.

Technology Game Changer

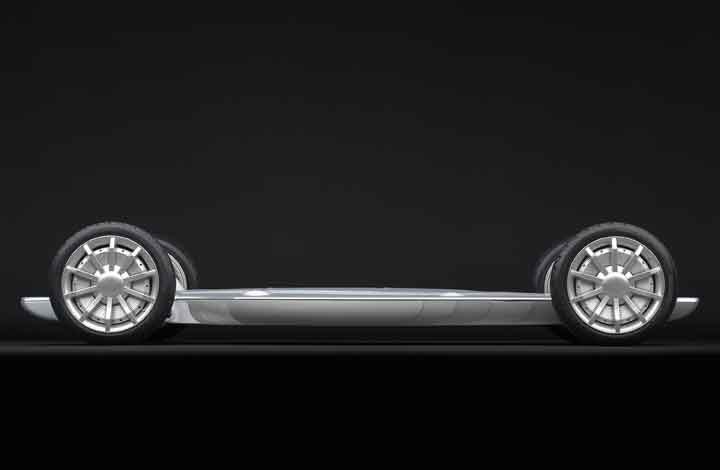

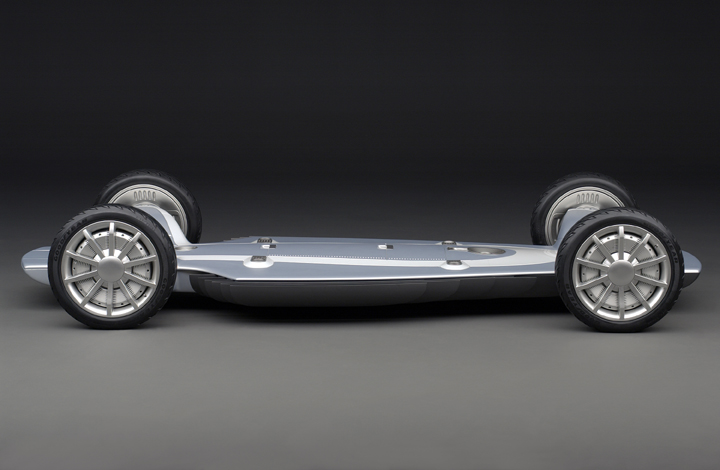

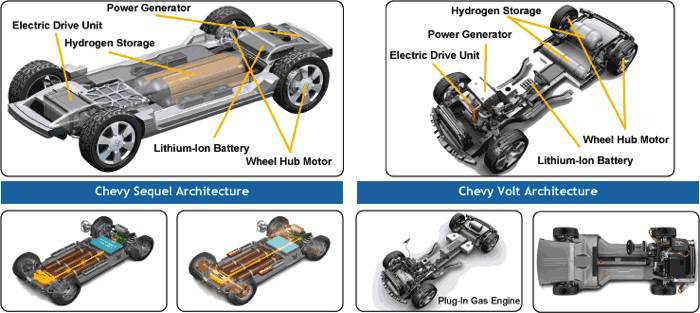

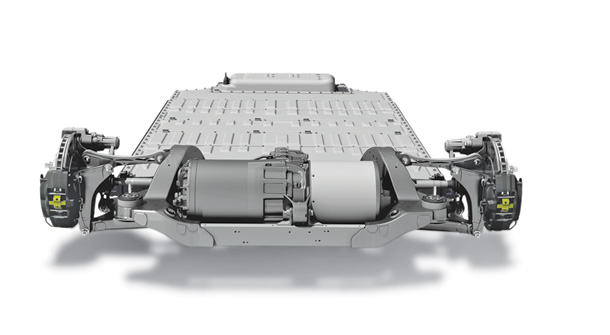

An adaptable, scalable, modular, and upgradeable electric vehicle platform known as the skateboard. With the skateboard in place, new technologies and propulsions systems can be easily integrated and deployed within the structure, thus creating a practical path for development, improvement, and technology integration.

Electrifying the Vehicle

By eliminating mechanical linkages and conventional vehicle powertrain configurations, the Reinvention of the Automobile created a new future for transportation: it enabled plug-in-hybrids, alternative vehicle designs, modular assemblies, innovative interiors, and active vehicle systems and software networks.

Design as a Differentiator

When the concept of “design as an enabler” is embraced, vehicle technologies can be packaged into a modular vehicle array (the skateboard), thus freeing up design expression and function while creating new vehicle design vocabularies and new and improved vehicle interiors.

Software Enabled

By utilizing an electric infrastructure, vehicle controls can be improved upon with by-wire advancements; controls can also offer additional variations through new design vocabularies, features, and enhanced consumer experiences.

Vehicles

Patents

%

Reinventing an Industry

How the Moonshot Automobile Program began:

In 2000, Rick Wagoner, Chairman and CEO of General Motors, tasked an elite team with solving an unanswered question: “If we were reinventing the automobile today, what would we do?” Little did he expect that the world’s largest auto manufacturer would get its solution from someone from outside the industry…specifically, from then-29-year-old Adrian Chernoff, inventor of the electric skateboard platform, who is a visionary technologist, creative engineer and innovator who unlocked the solution and paved the way for a cleaner and technologically greener future of transportation.

The answer to reinventing the automobile—and the end results—far exceeded expectations. Innovations and developments achieved as a result of this far-reaching initiative yielded a series of design and technology vehicles that have since been showcased and driven all over the world. Nearly 50 awarded patents have come out of this program, and the world now holds the keys to a revolutionary electrified vehicle platform. The advanced technologies that the GM AUTOnomy and its successors brought to the table not only changed the perception of the automobile, they broke the automotive mold by loosening the constraints of transportation.

If this vision of the future is correct, the future is the GM AUTOnomy. To get there, we must pursue each evolution backwards in order to bring our vision closer to becoming a reality. The Chevy Volt—the first plug-in hybrid vehicle and the first one of its kind to be mass-produced for the public—has paved the way for us to reach this ultimate future, a future that includes many innovative elements.

Electric Platform as an Enabler

An adaptable, scalable, modular, and upgradeable electric vehicle platform known as the skateboard. With the skateboard in place, new technologies and propulsions systems can be easily integrated and deployed within the structure, thus creating a practical path for development, improvement, and technology integration.

Design as an Enabler

When the concept of “design as an enabler” is embraced, vehicle technologies can be packaged into a modular vehicle array (the skateboard), thus freeing up design expression and function while creating new vehicle design vocabularies and new and improved vehicle interiors.

Electrical Controls as an Enabler

By utilizing an electric infrastructure, vehicle controls can be improved upon with by-wire advancements; controls can also offer additional variations through new design vocabularies, features, and enhanced consumer experiences.

Less is More as an Enabler

By eliminating mechanical linkages and conventional vehicle powertrain configurations, the Reinvention of the Automobile created a new future for transportation: it enabled plug-in-hybrids, alternative vehicle designs, modular assemblies, innovative interiors, and active vehicle systems and software networks.

- Actualizing Innovation 50%

- Design Freedom 80%

- Technology Innovation 75%

- Technology Availability 50%

- Industry Differentiator 90%

- Industry Transformation 100%

The Story behind Reinventing the Automobile

In order to answer Wagoner’s call to action, to create big and bold innovation to make General Motors a leader again, Larry Burns, GM’s VP of Research & Development in Warren, Michigan, brought in Adrian from Albuquerque, New Mexico. Adrian quickly became a founding member of the Design and Technology Fusion team. (He was the only member to be recruited from outside the industry.) Upon his arrival at GM, Adrian dove head-first into the corporation and its industry, meeting with all the R&D and Design directors to get a firm understanding of current and future developments and advances in automobile technologies and design methodologies. In addition to studying the entire General Motors global portfolio and going through mountains of books to understand the history of the automobile, Adrian researched state-of the-art styling, design, materials, technologies, prototypes, and manufacturing processes both inside and outside the industry. He began to view the history of the automobile as a progression of improvements that had become the standard of modern transportation. The “state of the art,” he realized, was more “the state of evolution” rather than being a revolution. Nothing had been done to really redefine the industry. There were kernels of opportunity, however—moments of insight and flashes of invention that Adrian could use to transition all of his accumulated knowledge into potential future answers.

After eight intensive weeks of research and ideation, Adrian assessed, identified, and answered the previously-unresolved question of how to reinvent the automobile. The answer required shuffling off the old way of thinking and replacing it with a new way of thinking: the solution wasn’t about solving a particular problem, it was about inventing and creating an entirely new way to design and manufacture vehicles. Adrian’s breakthrough system resulted in the invention of a revolutionary “skateboard” platform and an electrified vehicle architecture.

The Revolutionary Skateboard Platform

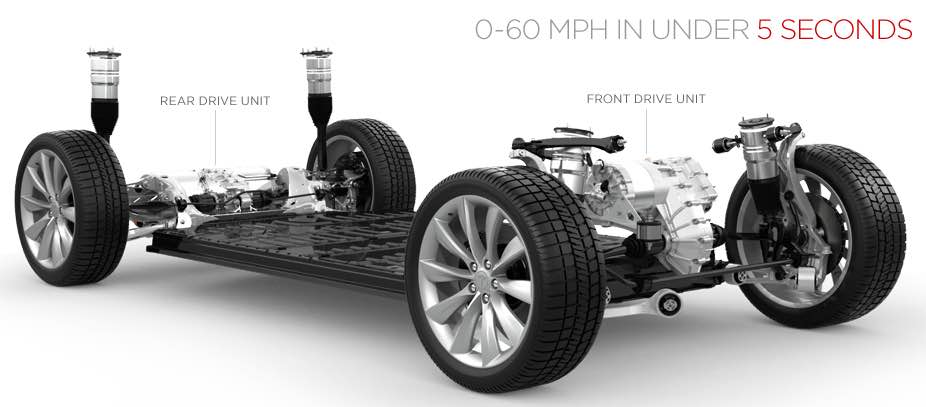

Two enablers came into play when Adrian began borrowing from the computer industry and the airline industry. One was incorporating the philosophy of “intel inside” and infinite customizations of what one could put into and plug into a computer; the other was adapting technological advancements in airplanes to electronic by-wire systems. By doing this, vehicles could become smarter, better integrated and electrified. In short, a revolutionary system and platform could be created.

From steering and driving to braking and accelerating, communications could flow from driver to vehicle through a robust architecture of software and electrical driver controls. Upon examining and extrapolating which elements needed to be separated in order for the vehicle to be customized, it began to make sense to separate the wheels and the engine from the driver. That way, under-the-hood elements could be configured in a multitude of possibilities; likewise, when the historical linkages and placements of the engine, drivetrain, steering column, pedals, etc. were eliminated, the occupants could be separated, thus freeing up interior engineering constraints from the vehicle’s hardware.

To enable an entirely-electrified architecture meant removing all of the fixed mechanical arteries of the vehicle and replacing them with electronic controls and connections. That enabled the driver to communicate via electronic signals, thus separating the physical wheel-driver connections and the wheel-engine connections. Electric motors would then replace the transmission, and electric power would be provided by batteries, generated from a traditional engine, or generated from an alternative power source such as a state-of-the-art hydrogen-powered fuel cell.

With this system, for the first time, a vehicle could be clearly separated into two unique segments: a vehicle body and a vehicle skateboard. (The powertrain and vehicle systems could be smartly packaged and placed into a new integral architecture known as the skateboard.) The occupants could travel inside a newly-structured vehicle body where the interior space could be optimized to offer new features, functionalities, and freedoms. The two vehicle segments could be joined by means of a docking-station scenario, wherein a data port docking connection could allow data to flow from one segment to the other. A series of mechanical locks would affix the body to the base.

This novel system would function as a blank slate to designers. With the vehicle systems packaged in the skateboard, the exterior and interior of the body could be designed in limitless ways and with endless possibilities. This freedom could unlock new design forms and new ways to use and interact with vehicles of the future. In essence, the skateboard segment could be engineered to last for 20 years…with potential upgrades and enhancements tripling or quadrupling its lifespan. Vehicle bodies could be swapped as desired or as necessary. In fact, skateboards could be standardized and optimized for crashworthiness, functionality, and software adaptability, then be manufactured and distributed all over the world. Global manufacturing would even allow the vehicle bodies to be customized to suit specific regions and cultural tastes; regional identities could be preserved even as design expression could be embraced.

“If our vision of the future is correct, and we think it is, AUTOnomy could reinvent the automobile and our entire industry.”

“We look at this technology as enabling us to create a number of exciting new body styles for consumers to choose from.”

“This is like a blank canvas, and you can paint whatever you want on top.”

“AUTOnomy is more than just a new concept car; it’s potentially the start of a revolution in how automobiles are designed, built and used.”

“Electric motor innovation supported the first wave of automotive growth a century ago with the electric starter, which eliminated the need for a hand crank and revolutionized automotive travel for the customer. We think the electrification of today’s automobiles will be just as revolutionary and just as beneficial to our customers.”

CHIEF VEHICLE ARCHITECT

Shortly after innovating a way to reinvent the automobile, Adrian Chernoff was appointed Chief Engineer and Vehicle Architect of the reinvention program. Working at the epicenter of GM’s innovative efforts, he helped initiate and lead the program with Chris Borroni-Bird, Director of Design and Technology Fusion. Together, they aligned executives across the organization to support the team in creating their new vision of the future. This included generating support and momentum across GM’s silos: marketing, design, manufacturing, and engineering. Work began in earnest. Creating sketches and story boards (the visual identity and design strategy was created by design genius Tucker Johnson in conjunction with the Advanced Portfolio and Exploration Group, a.k.a., APEx) was followed by visoneering and creating the technology and vehicle development plans.

Support began to build across the organization. Finally, GM’s Automotive Strategy Board gave the program its full blessing. With the Board behind him, Rick Wagoner gave Larry Burns the “go” and green-lighted the program. After gaining top-down support, Chris began drawing on his fuel cell experience to orchestrate the program, and Adrian began the process of making it real by designing, developing, and executing the creation and development of several advanced-technology vehicles. Part of that technical leadership meant cooperating closely with and advising executive management teams.

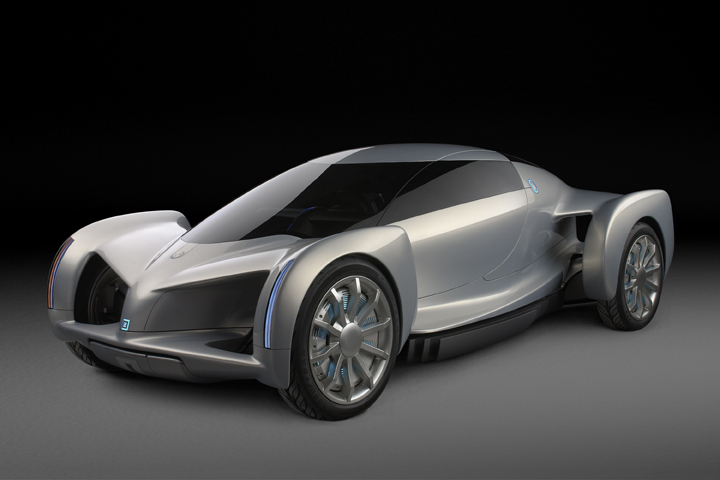

The program was dubbed the Reinvention of the Automobile. Over the next six years, it resulted in a series of fresh vehicles designed from the ground up. These vehicles were all based on the new revolutionary skateboard architecture that was equipped with alternative-energy solutions, software, and adaptable electronic controls. The first vehicle, the GM AUTOnomy, was ideated and created in just six short months. Its crowning glory came when Rick Wagoner rolled it out as GM’s showcase vehicle at the North American International Auto Show (NAIAS) in Detroit.

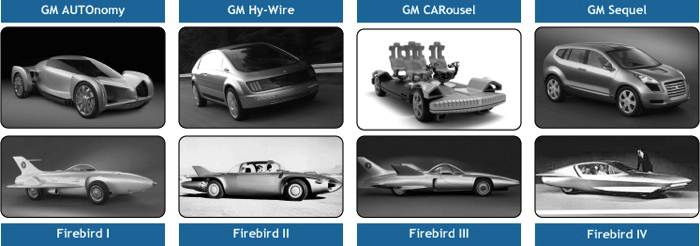

The AUTOnomy received much fanfare—it garnered many rave reviews and awards and was acclaimed as being the biggest breakthrough in automotive transportation to have hit the road in the last 50 years. Eight months later, the expanded team of four (Chris Borroni-Bird was the Programs Director, Adrian Chernoff was the Chief Architect and Program Manager, Robert Vitale was the Body Electrical Engineer, and Mohsen Shabana was in charge of chassis fuel cell engineering) introduced the world’s first entirely new, fully drivable system: the GM Hy-Wire. The HyWire debuted at the Paris Auto Show and was introduced at the NAIAS in Detroit four months later. The vehicles that followed included the GM CARousel, the GM Sequel, and the GM Chevy Volt.

The Principal Inventor

Adrian Chernoff was the Chief Vehicle Architect and Strategist in the Reinvention of the Automobile program. As the program’s principal inventor and product manager, he was the one who created the universal, highly adaptable, and flexible skateboard architecture. Utilizing out-of-the-box thinking, he combined advanced propulsion systems, electronic controls, electric motors, computer software, advanced materials, and novel packaging to yield an elegant electric-drive skateboard. The resulting innovation allowed for a plug-and-play scalable chassis where the only moving parts are protons, electrons, and the wheels.

As the Chief Architect, Adrian led, coordinated, and managed large, global multi-disciplinary teams and resources. He and his team collaborated with many other partners throughout the development, research, design, build, execution, and roll-out of the first vehicle in the program, the visionary General Motors AUTOnomy. The AUTOnomy was followed by with the creation, development, engineering, design, and build of the world’s first drivable by-wire system with an advanced propulsion system (the General Motors Hy-Wire). Throughout the program, Adrian worked with more than 150 partners and contributors, including GM Opel, Stile Bertone, and SKF. The Hy-Wire was succeeded by the creation, concept testing, development, design and build of the GM CARousel, the world’s first vehicle to be fully designed using strictly CAD software. (It was built by Stile Bertone in Italy.) Finally, Adrian was a core team member in creating, developing, and engineering the world’s first long-range vehicle, the GM Sequel, while developing advanced vehicle concepts and reinventing vehicle interiors across GM’s silos. He also managed and worked with outside partners such as Continuum and Applied Minds.

Building Innovation from the Ground Up

At GM, Adrian not only revolutionized the vehicle experience by inventing and creating new technologies and processes, he also managed business concerns—project resources, budgets, and timing—and led a team of design and technical professionals to exceed development milestones in delivering complex vehicle systems. He took ideas from development to execution, propelling vehicle designs, development programs, and product deliveries of several unique and visionary concept and pre-production vehicles.

Adrian’s experiences at GM were not typical: the project he was tasked with and the implementation of that project were spearheaded by the General Motors senior leadership and Automotive Strategy Board. The vehicles had to be created with the existing market conditions of the organization in mind, and GM is a very diverse and large organization with highly specialized functional areas that are separated into unique silos. This means that the company’s internal activities operate independently; operations are leveraged and/or integrated both globally and within the US.

Adrian’s job was two-fold: he was to create system-wide breakthroughs in terms of design and technology and he was to navigate and leverage the organization from the inside out to achieve success. Doing so required him to optimize development among core teams and product development functions alike. His work resulted in creating the future of the automobile. He achieved this monumental task by driving technology development, bridging independently-operating silos, orchestrating the build and development of the vehicles (and their delivery), and working with GM’s communications and marketing departments to make sure that very powerful ideas, concepts, and products were conveyed to the industry and to the public. The end result? The automotive industry acknowledged that GM’s new vehicles and technologies were the biggest thing to have happened to the automobile in the last fifty years.

But Adrian didn’t come to GM because he was an automobile expert. He was recruited because of his creativity, strategic thinking, engineering expertise, business experience, and technical insight and know-how. He was brought into the company to help break the automotive mold—given his experiences at NASA, DISNEY and the Los Alamos National Labs, he was identified as a valuable asset because he was capable of bridging engineering, design, and business. GM knew that Adrian would enable innovations and that he would be an entrepreneur and a leader within the organization.

During his tenure at GM, Adrian developed disruptive technologies and innovations spanning the diverse and divergent fields of manufacturing, engineering, design, electronic controls, vehicle structures, and retail methods. His largest contribution to the organization was his role in creating and developing the world’s first-ever skateboard car: a zero-emission, hydrogen-fueled car propelled by wheel hub motors and controlled with electronic signals. His responsibilities included designing and building three advanced vehicles in various phases of development (from concept vehicles to pre-production versions), integrating diverse departments (Design, Engineering, R&D, and Communications), authoring and filing over 60 patent applications, kicking off technology development programs, conducting over 30 cross-organizational brainstorming sessions, managing teams ranging from ten people to over 300 people, managing tens of millions of dollars, spearheading innovation activities, managing technology innovation at multiple (and global) R&D and design facilities and supplier facilities, and managing project budgets, timing, and resources.

Building on a legacy of Reinvention

When Adrian Chernoff, inventor of the electric skateboard platform used by Tesla and VW, and his team were tasked with the Reinvention of the Automobile, they thought the best way to start was to reengage GM’s rich corporate history. It had been 50 years since the introduction of the historic Firebirds, the team realized. Those Firebirds represented the first true merging of technology (R&D) and design (styling) at General Motors. The original series of visionary Firebirds—I, II, and III—had been revolutionary during their time. They combined state-of-the-art technology, turbines, new materials, and futuristic design thinking. Merging those two discrete worlds of R&D and styling was an industry first, and that merger had also been the last true collaboration in over 50 years.

The evolution of the GM AUTOnomy began by renewing the historic integration and collaboration between GM’s separate divisions. (That was the first time in over half a century that such a collaborative effort had been made within the company.) It should therefore be no surprise, then, that the press and automobile experts claimed that the General Motors AUTOnomy was the biggest thing to come along in 50 years!

“The fact that we developed Hy-wire as a drivable concept vehicle in just eight months (from its introduction in Detroit) shows our commitment to this technology and the speed at which we are progressing. With AUTOnomy, GM shared a vision. Hy-wire accelerates our progress with a functional proof of concept which strengthens our confidence in our ability to gain marketplace acceptance.”

“By combining fuel cell and by-wire technology, we’ve packaged this vehicle in a new way, opening up a new world of chassis architectures and customized bodies for individualized expression.”

The Firebirds and the Reinvention Vehicles

There are some amazing correlations between the famous Firebirds of the past and the current (and future) Reinvention of the Automobile. The following comparisons are interesting, because although these similarities are accidental, the two platforms share some fascinating coincidences.

FIREBIRD I AND THE AUTONOMY: The Firebird I (XP-21) was introduced in 1952. Fifty years later—in 2002—the GM AUTOnomy was introduced. Both vehicles are made of fiberglass and were designed for only a few occupants (the Firebird I was intended for one occupant and the Autonomy for two). The leader of the Firebird I’s styling was the VP of Design, Harley Earle; the leader of the Firebird’s technology development (the Whirlfire Turbo-Power engine) and chassis development was Charles McCuen, the VP of R&D. Likewise, the GM AUTOnomy’s design was spearheaded by the VP of Design (Wayne Cherry) and the advanced power train was led by the VP of R&D (Larry Burns).

FIREBIRD II AND THE HY-WIRE: The Firebird II was a family sedan that seated four passengers; the GM Hy-Wire was a touring sedan with seating for five. The Firebird II was made from an all-titanium body; the Hy-Wire was intended to be made of a new aluminum-anodized-alloy material that would have nullified the need to paint the body. (Unfortunately, that material proved to be too expensive to tool and demonstrate.) The Firebird II featured a regenerative gas turbine engine and the world’s first disc brakes; the Hy-Wire introduced the world’s first fully operational fuel cell system and also featured the world’s first by-wire steering, accelerating, and braking system.

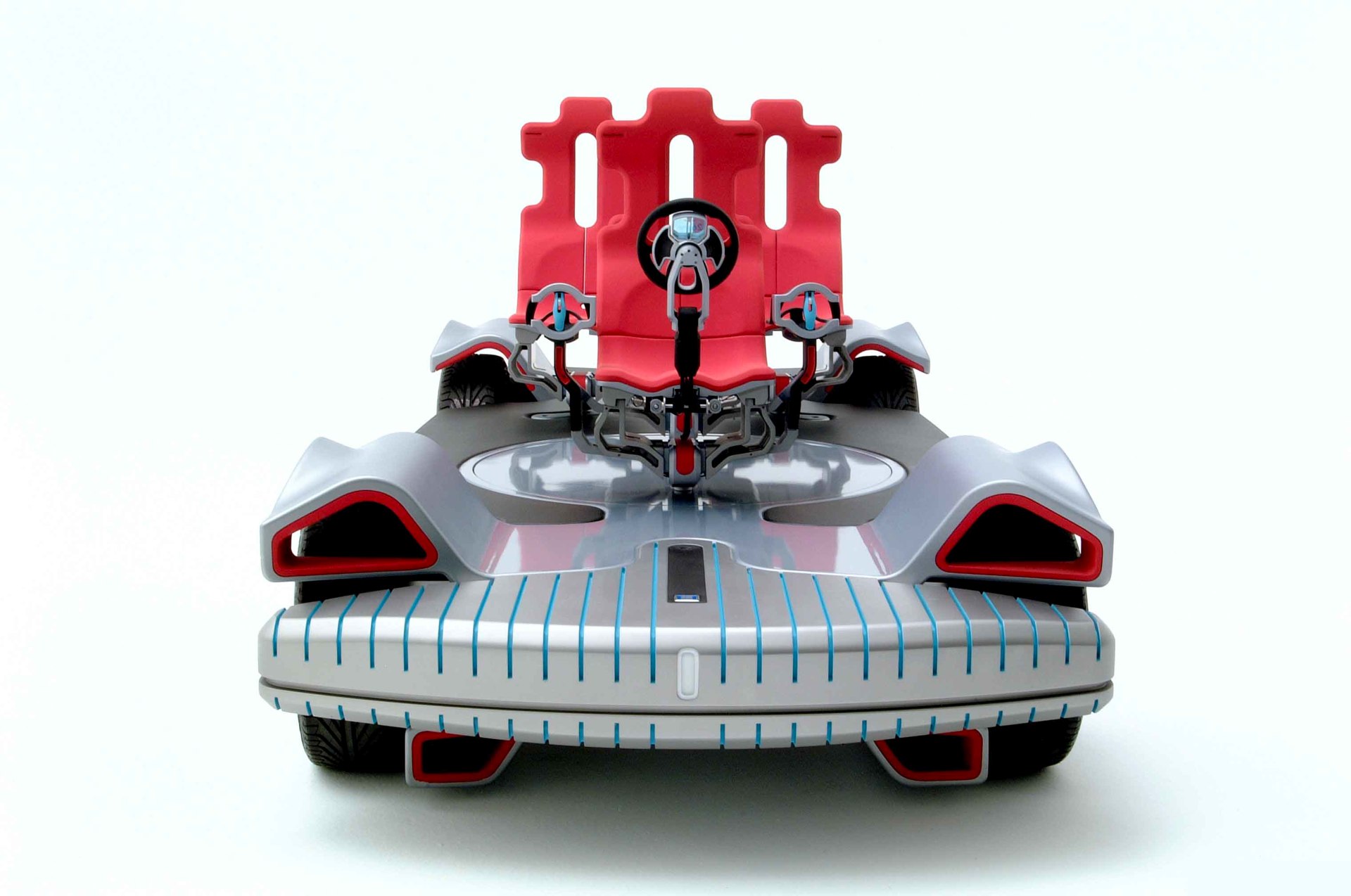

FIREBIRD III AND THE CAROUSEL: The Firebird III featured the first advanced control system (called “Unicontrol”) that allowed a driver to drive using the world’s first single-stick joystick control, thus eliminating the conventional steering wheel, brake pedal, and accelerator. The General Motors CARousel also eliminates the traditional brake and accelerator pedals and offers two revolutionary methods of driving wherein braking the vehicle is accomplished more quickly than it is with pedal-based braking systems. (The first of these solutions enhances the steering wheel with by-wire braking and accelerating controls; the other eliminates the steering wheel entirely and introduces two synchronized by-wire rotary control arms.)

FIREBIRD IV AND THE GM SEQUEL: The Firebird IV was a gas-turbine vehicle with four high-back, countered bucket seats. It also featured a refrigerator, a television, and joysticks located in the armrests. Due to the airflow needs of the turbine, horizontal air slots were positioned at the front of the vehicle. The General Motors Sequel also features four high-back seats (with an optional fifth) that rotate and swivel; like the Firebird IV, the Sequel also offers unique accessories such as storage features, flip-up displays, and video screens. And again, like the Firebird IV, the large front grill of the Sequel is designed to take in large amounts of air to cool the fuel cell system. The Firebird IV was designed under the leadership of Bill Mitchell, the new VP of Design (he replaced Harley Earle). During work on the Sequel, Ed Welburn replaced his predecessor, Wayne Cherry, as the new VP of Design.

The best form of Flattery

A selection of vehicle programs leveraging the GM Skateboard and Reinvention Program

TOYOTA COPIES THE AUTONOMY AND HY-WIRE: In the highest form of flattery, a year after the unveiling of the GM AUTOnomy, Toyota showcased their version of electrified architecture with Toyota Fine-N, a copycat concept vehicle with fuel cells, drive-by-wire steering, and wheel motors. A year later, Toyota did the same thing when the company copied the GM Hy-Wire. That time, Toyota called their concept the Toyota Fine-S.

SUZUKI’S MOBILE TERRACE LEVERAGES THE GM HY-WIRE SKATEBOARD: The Suzuki Mobile Terrace—showcased at the Tokyo Motor show in late 2003—was a show car based on the GM Hy-Wire skateboard chassis; like the Hy-Wire, the Mobile Terrace incorporated fuel cells and driving, steering, and braking by-wire technology. The six-seater, mini-van-type vehicle featured extensive visibility for its occupants, abundant interior spaciousness, and innovative driver controls and displays. Innovations included a canopy that was created by opening the roof sides, quad-opposing sliding doors, and a social “meeting place” made by extending the seat bases outside the vehicle and flattening the 22-inch driver’s display control panel into a social, interactive table. The Mobile Terrace is rather like a living room on wheels—one moment, it can be used to go to a destination, and the next minute, it is the destination.

AUTONOMY DESIGN COMPETITIONS: Over the years, many design competitions have used the AUTOnomy skateboard as an enabler for design. One such competition was promoted by Car Styling Magazine; others have been held at design schools such as the Art Center College of Design in Pasadena, California, the College for Creative Studies in Detroit, Michigan, and Strate Collège in Paris, France. GM has also hosted many competitions for its summer interns wherein the primary focus was on branding and creating innovative future GM vehicles based on the skateboard chassis. In addition, the Massachusetts Institute of Technology (MIT) researched and considered hydrogen-distribution technologies stemming from the AUTOnomy (with a $5,000-prize up for grabs) and in conjunction with the Smart Cities Group, the MIT Media Lab leveraged the GM AUTOnomy and its drive-by-wire functionality to create concept vehicles with world renown architect, Frank O. Gehry.

ITALDESIGN’S VADHO EMBRACES THE REINVENTION OF DRIVING PATENTS: At the Geneva Autoshow in 2007, the VAD.HO (by Italdesign’s Giugiaro) showcased technology that had first been integrated in the GM Hy-Wire: by-wire controls, hydrogen technology, and electrically-controlled foot rests. Although the VAD.HO does not leverage fuel cells, it still runs on hydrogen. The vehicle features joystick driver controls that are attached to the seat. They move back and forth, eliminating wrist rotation with by-wire controls. The novelty of the VAD.HO patent applications may be a moot point, though, considering that elements of the joystick design are patent-protected by at least one of GM’s patents (Patent# 6,898,496, Pivoting Arm Driver Control Input Device).

THE CHEVY VOLT IS THE NEAR TERM VERSION OF THE REINVENTION OF THE AUTOMOBILE: In January 2007, GM unveiled an architecture called E-Flex as part of the Chevrolet Volt concept vehicle. (The Volt is a plug-in hybrid that’s electrically powered by a plug-in battery system.) The concept showcases the same technologies that are featured in the GM Hy-Wire and the GM Sequel skateboard technology platforms. These overlapping technologies include a fuel cell propulsion system, hydrogen storage tanks, batteries, one electric motor for the front wheels, and electric motors mounted within each rear wheel. The only difference between the Hy-Wire/Sequel and the concept Volt is the elimination of the skateboard and the use of a mechanical steering column. The ability to have different propulsion systems (traditional gas or diesel, E-85 bio-fuel, batteries, or other electric powertrains) was covered in the GM AUTOnomy program. The good news is that the Chevrolet Volt is targeted for production in 2010 and will most likely have an internal combustion engine and a front electric motor. The program lives on, albeit in a nearer-term solution!

TREXA COPIES THE AUTONOMY SKATEBOARD: In 2010, Trexa, a U.S. startup, announced that an electric vehicle development platform would be produced the same year. This platform would utilize the patents covered under the Reinvention of the Automobile—i.e., the modular and scalable AUTOnomy skateboard platform (with its docking system for vehicle bodies) that’s enhanced by programmable electronics and advanced propulsion technology. Quoting directly from the General Motors AUTOnomy playbook, Josh Davis, Trexa’s Director of Marketing, said, “Without an internal combustion engine and exhaust system, all of the battery, driveline, and power electronics – everything that makes a vehicle go – can be contained in a low-profile enclosed structure that lends itself to unlimited design possibilities.”

LOCAL MOTION (Formerly Weng Motors) COPIES THE AUTONOMY SKATEBOARD: In 2010, Weng Motors, out of Stanford, copied the AUTONOMY platform by using by-wire steering and wheel motors in a flat skateboard chassis. Led by founders John Stanfield and Clement Gires the company recently evolved into Local Motion and was showcased at the Launch Conference in 2012. The electric chassis has a built in safety cage for occupants and is being readied for production and sale in 2013/2014 at $12,000 for corporate campuses like Google, Microsoft and VMware and potentially for consumers thereafter. Local Motion is labeling the vehicle a “social vehicle” to differentiate it from other vehicles as it is utilizing software and sensors. Local Motion is currently intended for short distance commuters. Interestingly, the production vehicle looks a lot like the Hy-Wire test platform with a fiberglass windshield and seats attached to the top of the electrified chassis.

TELSA MOTORS UTILIZES THE SKATEBOARD PLATFORM: Late in 2003 Tesla was formed after the GM Autonomy’s reveal and just before the GM Hy-wire. In 2004 JB Straubel (CTO), Martin Eberhard (CEO), Marc Tarpenning (CFO) and Elon Musk (Chairman and Head of Product Design) headed up the company. It launched the Roadster in 2006 and The Model S in 2012.

Related Projects